Engineering powerkote has the exclusive distribution and applications rights for techline coatings usa s range of renowned ceramic coatings that were originally designed to handle re entry temperatures for space vehicles in the.

Engine platinum ceramic coating.

After restoring cracked parts of engine is recovered and.

Cracked parts have high electric potential and charged particles are moved selectively into cracked parts.

Thermal barriersin theory heat management offers great potential for improving an engine s power output.

Often ceramic based thermal barrier coatings tbcs are used to reduce heat migration.

Tight platinum metallic cohesion is conducted by heat and pressure.

Thermal barrier coating designed for performance engines running.

Powerkote pty ltd is a leading distributor and applicator of microfilm high temperature ceramic coatings.

12 5 1 compression ratios nitrous oxide n2o supercharged or turbocharged.

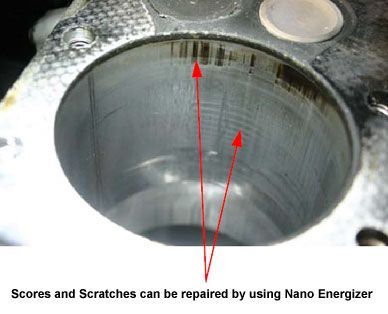

Nano ceramic powder mixed with engine oil restores worn out parts of engine.

The system offers a scientifically tested system of protective treatments that outperform anything else available on the market.

Platinum is 20 times harder and 6 times smoother than steel these nano particles create a hard smooth coating layer on all the friction surfaces moving parts inside the engine zirconium coating acts like a thermal barrier coating inside the engine cyllinder liner and prevents heat loss.

Platinum is the high performing solution for your car powered by ceramic coating experts gtechniq.

Excellent ceramic cermet coating.

For all other applications use cbc2 above.

.png)