These resins form durable laminates and.

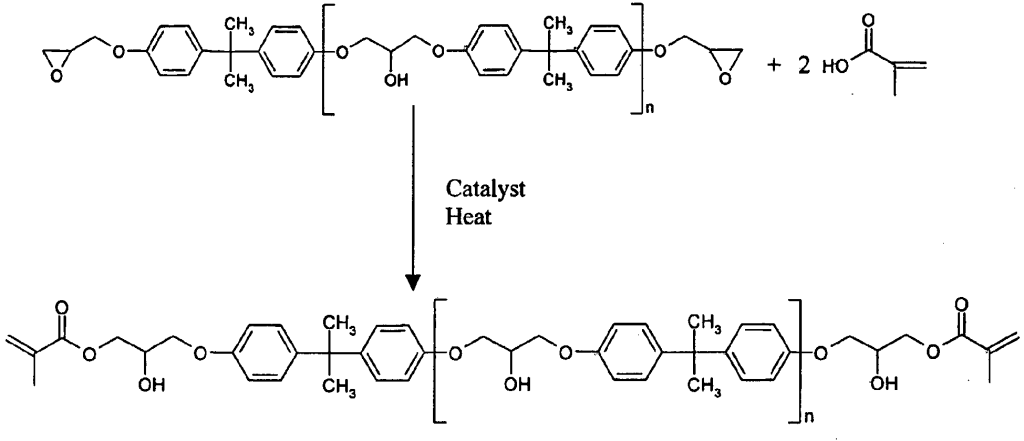

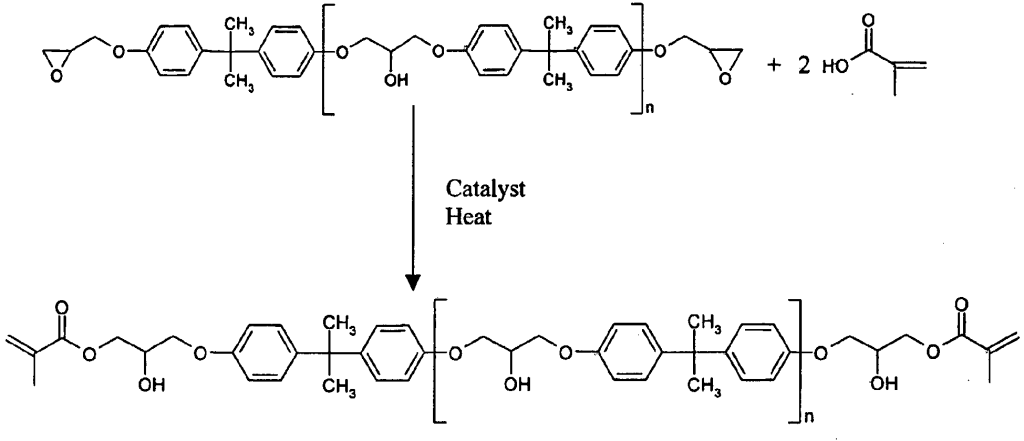

Epoxy vinyl ester resin structure.

The two main types of epoxy resins are bisphenol a diglycidyl ether dgeba and epoxy phenol novolac epn.

Bisphenol a based epoxy vinyl ester resins provide high chemical resistance and mechanical strength.

The diester product is then dissolved in a reactive solvent such as styrene to approximately 35 45 percent content by weight.

Epoxy vinyl ester resins ver are an important class of high performance thermoset molding resins.

Vinyl ester resins are produced by the reaction esterification between an epoxy resin and an unsaturated monocarboxylic acid.

They are produced by the addition of α β unsaturated carboxylic acids to epoxy resins.

The vinyl groups refer to these ester substituents which are prone to polymerize.

Vinyl ester resin or often just vinyl ester is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids.

While they have high mechanical strength values similar to epoxy resins they are easy to apply similar to unsaturated polyester resins.

The molecular structure of vinyl ester resins is similar to that of polyesters but differs primarily on the location of their reactive groups which are positioned only at the ends of the chains.

Essentially they comprise a base of polyester resin strengthened with epoxy molecules in the backbone of the molecular chain.

Vinyl esters also use peroxides e g.