Epoxy vinyl ester resins also find uses in coatings particulalry for the marine building and construction industries due to their excellent corrosion and weathering resistance.

Epoxy vinyl ester resin uses.

To cover wood a laminate using epoxy resin and 10 oz cloth will yield a much better job than 10 oz.

It adds excellent strength rigidity adhesion water and chemical resistance.

Vinyl ester resin or often just vinyl ester is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids.

Essentially they comprise a base of polyester resin strengthened with epoxy molecules in the backbone of the molecular chain.

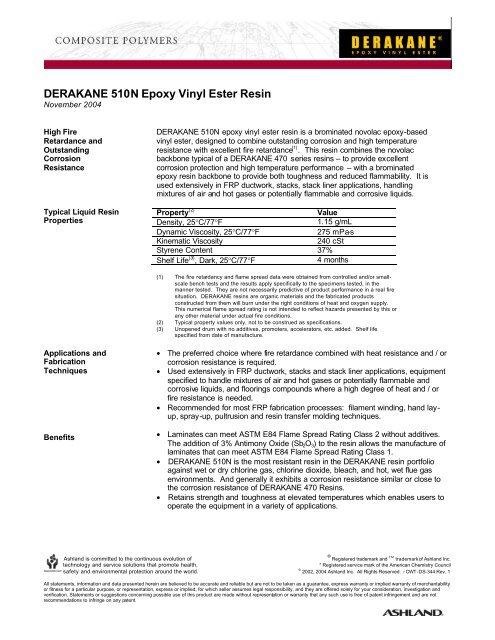

Pip ve fr resin is a fire retardant brominated bisphenol a epoxy vinyl ester resin.

Resin has a short shelf life.

The vinyl groups refer to these ester substituents which are prone to polymerize.

Try to store the resin in a cool dry place or refrigerate do not freeze it to extend the life of the resin.

It is important to note that of the three vinyl ester resin will provide the highest corrosion resistance temperature resistance and elongation toughness.

Vinyl ester has a shelf life of 3 months.

Derakane momentum epoxy vinyl ester resins are organic materials and will burn under the right conditions of heat and oxygen supply.

Advances in fire retardant materials 2008.

Epoxy adheres to wood much better than polyester does.

This product allows the use of standard mekp exhibits excellent.

However most are prepared solely with reactive vinly type monmomers.

Vinyl ester resins are produced by the reaction esterification between an epoxy resin and an unsaturated monocarboxylic acid.

Vinylester is essentially a styrene modified epoxy resin.

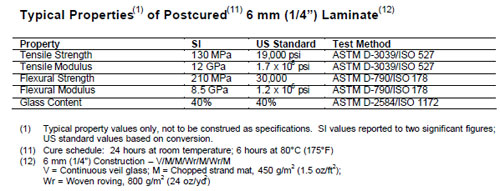

Vinyl ester resins are the binary resin systems containing a dimethacrylate monomer from which the cured material gains most of its properties and a reactive monomer such as styrene which acts as a reactive diluent and also takes part in the cross linking reaction.

It can be used to produce glass reinforced laminates with excellent impact and stress resistance.

Brief product description derakane 455 400 resin is an unpromoted highly crosslinked novolac epoxy vinyl ester.

This product provides corrosion control to a wide variety acids and alkalis.

In some cases conventional solvents such as xylenes are also used.

The diester product is then dissolved in a reactive solvent such as styrene to approximately 35 45 percent content by weight.

The styrene in the polyester or vinyl ester resin will melt it.

Epoxy resin should be used.

Vinyl esters also use peroxides e g.